The Customer

3S Engineering and Design is an Engineering, Procurement, and Construction (EPC), Texas-based company, that works with numerous major oil and gas producers in the Permian Basin of New Mexico and Texas.

The Client’s Challenge

One of 3S Engineering and Design’s clients was faced with the challenge of compliance with a new set of regulations limiting methane gas emissions at over one thousand of their client’s facilities in the Permian Basin in southeastern New Mexico.

This major oil and gas producer needed an efficient method for tracking and meeting State methane emissions regulations at these Permian Basin well heads in New Mexico. 3S Engineering and Design asked Team D3 to partner with them on the alignment of Autodesk Civil 3D, Esri ArcGIS, and ArcGIS Field Maps. 3S Engineering and Design, while very experienced with Autodesk Civil 3D “facility modeling” and “field assessment,” did not have a strong background in Geographic Information Systems (GIS) as well as the required database structuring.

The client needed to coordinate Esri ArcGIS and ArcGIS Field Maps well location data with Autodesk Civil 3D drawings of the facility, equipment locations, access roads, and other key drawing data. The combined data along with assessed information, equipment information, and specifications are necessary to create methane emissions monitoring workflows and equipment upgrade construction packages by 3S Engineering and Design for the client.

- To help their clients meet their regulatory requirements promptly and effectively.

- To build a greater knowledge of the CAD to GIS process enabling them to help other clients in the future.

- More time/cost-effective methods for managing client projects.

- A better understanding of project scope and components resulting in better decision-making by all parties.

- The ability to expand the 3S Engineering and Design catalog of services to grow their business.

- Find a way to ensure that they have a good definition and awareness of adjacent properties and roads that are not a part of their land and road lease agreements which can often result in heavy trespass fines.

The Solution

Team D3 prescribed and executed a comprehensive solution beginning with the creation of a compliant database structure that sets the stage for subsequent site monitoring. Secondly, the solution addressed the need for update and/or modification of “facilities” to meet the government emissions standards. This was accomplished by using CAD and GIS data to create construction packages that would allow work to begin quickly once it was decided modifications were needed. 3S Engineering and Design and Team D3 worked together to create the procedural processes and workflows that bring together the necessary drawing, permitting, and other information sets to make this possible. Custom programming was designed and implemented to automate many of these processes.

The Team D3 GIS team led by the GIS Technical Project Lead and Project Program Manager aided 3S Engineering and Design and their client in the analysis and division of the project into essential service phases. Field Data Collection was needed to pinpoint critical equipment and other critical field data points. 3S Engineering and Design employed StarLink satellite Internet to supply real-time field-to-office transfer of the data as well as make real-time changes to Computer-Aided-Design (CAD) files using the connections between Civil 3D and ArcGIS Field Maps. It was also essential to create multiple user interfaces for various consumers of the complex data that were not Civil 3D or ArcGIS users. Team D3 created dashboards that performed complex queries that presented resulting reports in a user-friendly interface.

Client’s Business Outcome

The implemented solution successfully addressed 3S Engineering and Design’s business challenges as well as achieving their corporate goals and objectives, including some unexpected benefits.

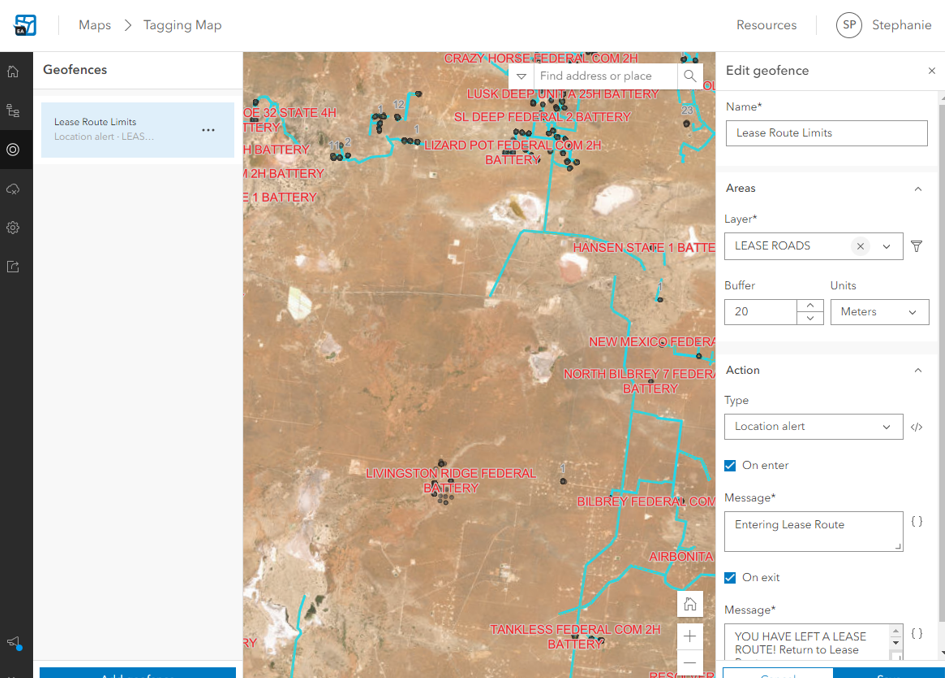

Because of excessive fines levied on the oil and gas producer caused by the unwitting trespass on roads not leased by the oil company, the project team was able to add “geo-fencing” to the well road maps that warn field teams before they venture outside of designated work areas. Secondly, one of the most tangible gains was the speed with which they can make CAD updates significantly faster using the integrated connection between Autodesk and Esri products.

3S Engineering and Design, historically, had collected data using paper before Team D3 created a digital and automated solution. 3S Engineering and Design determined that data collection with ArcGIS Field Maps was so much more accurate and efficient than their historic data collection methods using paper, that they decided to revisit “paper sites” using ArcGIS Field Maps and they still completed the task 3 weeks ahead of normal schedules. Field Mapping capabilities have created additional revenue streams for 3S Engineering and Design.

Conclusion

3S Engineering and Design was able to achieve its corporate project goals and initiatives because of its intentional adoption of the new digital solution throughout its corporate community. 3S Engineering and Design is realizing both expected and unexpected benefits now and is already discovering several ways in which they can expand the solution Team D3 developed to meet the growing list of regulatory requirements they face, along with the opportunity of updating other workflows and project lifecycle procedures in their organization.